When performing gas sampling with Tedlar bags, Kynar bags, Multi-Foil bags or FEP bags, the choice of fitting material is of critical importance. The fitting is in direct contact with the gas sample and, depending on the chemical properties of the gas, may affect chemical stability, adsorption behaviour, and overall measurement reliability.

Tedlar sample bags, originally developed by Chemours, are widely used in environmental monitoring, industrial emission measurements, and laboratory analysis. These bags are commonly supplied with either polypropylene (PP) or PTFE fittings. The appropriate choice depends on the type of gas and the sampling conditions.

Polypropylene is a lightweight and cost-effective polymer with good chemical resistance to many inert and non-reactive gases. PP fittings are generally suitable for routine gas sampling applications under dry conditions and with short contact times.

Limitations of PP:

PTFE is known for its exceptionally broad chemical resistance and near-inert behaviour. It is widely used in analytical and industrial environments where aggressive, reactive, or corrosive gases are involved.

Advantages of PTFE:

These gases may attack polypropylene and lead to material degradation.

In combination with humidity, these gases can form strong acids.

Polypropylene is generally not sufficiently resistant to these substances.

Especially critical at higher concentrations, in humid conditions, or during extended storage.

Under dry conditions, low to moderate concentrations, and short contact times, PP fittings are usually adequate for:

The selection between polypropylene and PTFE fittings for Tedlar bags should be based on the chemical nature of the gas, the sampling conditions, and the required analytical reliability. For critical applications involving reactive or corrosive gases, PTFE provides the highest level of chemical safety and sample integrity. For standard applications involving inert gases, polypropylene offers a practical and economical solution.

If desired, this content can be condensed for use on a product page or converted into a clear PP versus PTFE compatibility table for direct reference alongside your Tedlar sampling bags.

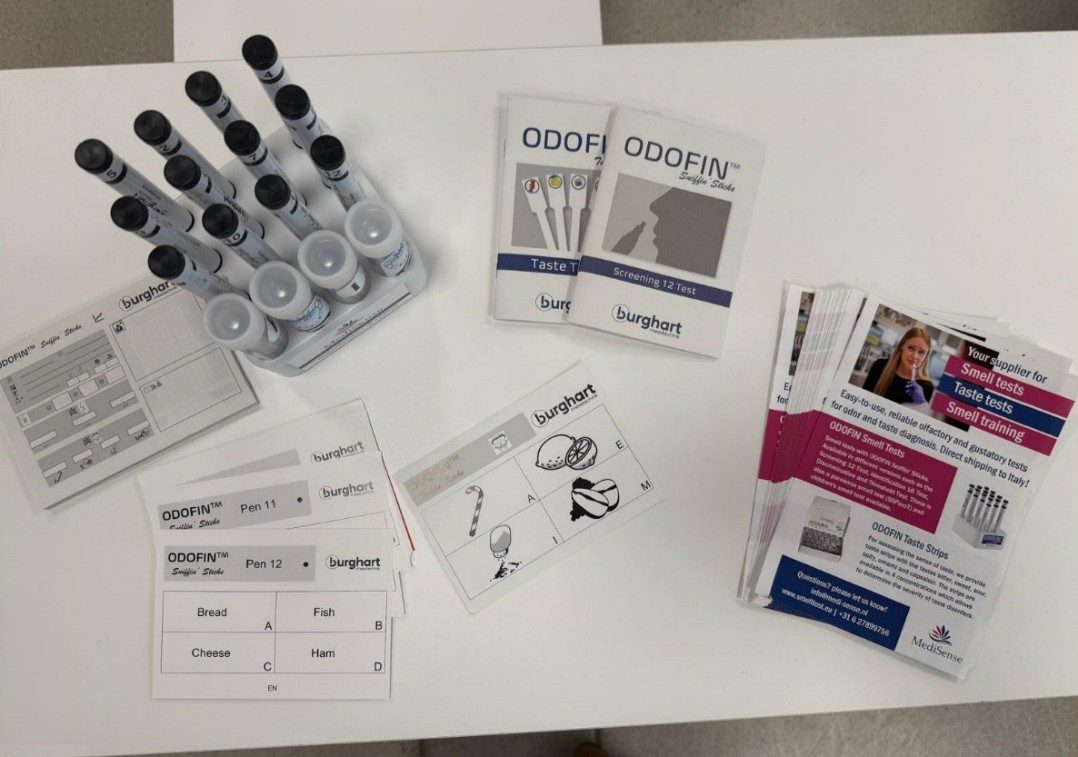

Gas sampling bags for air sampling. Competitive prices, reliable service, fast delivery and top quality air sampling bags. We supply various gas sampling bags such as:

Worldwide delivery, click here for the transport costs.

Delivery on account is possible. Contact us for a quote or order directly via the webshop.

Contact via info@medi-sense.nl or +31 (0)6 27899756

Various payment options are available such as iDeal, Sofort, BanContact and PayPal.